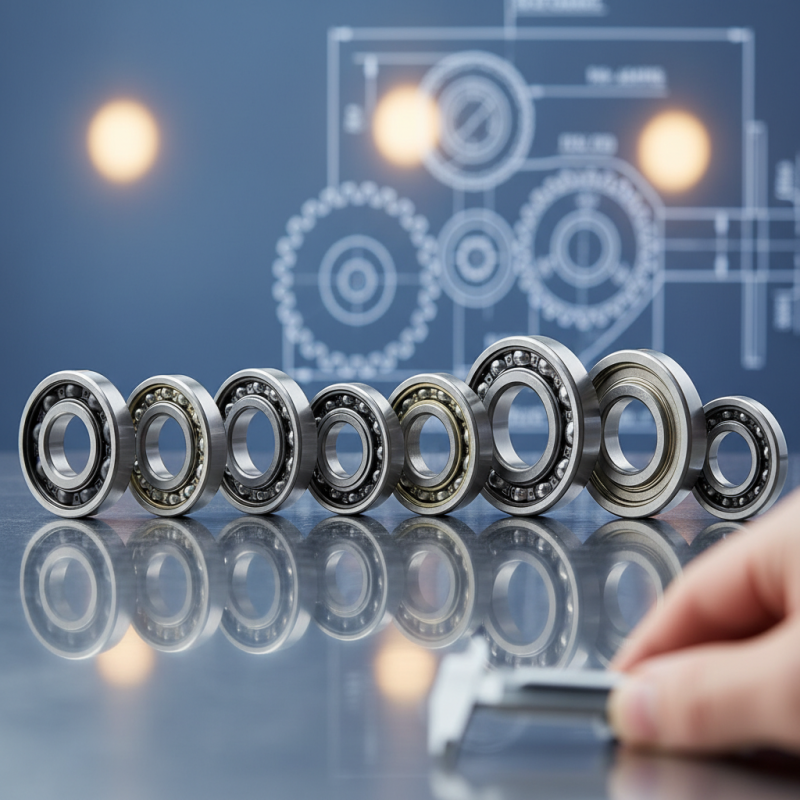

Choosing the right Ball Bearing can significantly impact performance and longevity in various mechanical applications. Ball bearings are vital components that reduce friction and support loads. However, selecting the perfect one can be challenging. Factors like size, load capacity, and material play a crucial role in this decision.

There are countless options available in the market. Some bearings may appear perfect but fail under specific conditions. Consider your project needs carefully. Pay attention to the manufacturer's specifications. Remember, a minor oversight could lead to costly failures down the line.

In the end, making an informed choice is essential. Take time to research and consult professionals. Your choice of ball bearing can either enhance efficiency or cause unexpected issues. Be thorough in your selection process. Evaluate all options before making your final decision.

When selecting a ball bearing, understanding the different types is crucial. Ball bearings generally fall into categories such as deep groove, angular contact, and thrust bearings. Each type has unique applications that can significantly affect performance. For instance, deep groove bearings excel in handling radial and axial loads in motors. They are ubiquitous in appliances and automotive components.

According to industry research, deep groove ball bearings account for approximately 50% of the global market. They are favored for their versatility and durability. Angular contact bearings, on the other hand, are often used in high-speed applications. Their design accommodates axial loads in one direction, making them essential for machinery requiring high precision. The demand for these bearings has increased, showing a growth rate of 4-5% annually.

However, choosing the right type can be tricky. Misjudging load requirements can lead to premature failure. Inadequate lubrication may also compromise performance. Often, engineers overlook these details when making selections. Staying informed about material options and application specifics is vital. Small decisions can have large impacts on efficiency and lifespan. It's easy to underestimate how critical these choices are.

When selecting the right ball bearing size, several key factors demand attention. The inner diameter, or bore size, must match the shaft's diameter precisely. A mismatch here can lead to operational inefficiencies and even failure. Consider the load type; different applications require bearings that handle radial or axial loads specifically. A bearing's load rating is crucial. Should you underestimate it, the bearing may wear out quickly.

Another aspect to ponder is the bearing's material. Common options include steel and ceramic. Each material has unique benefits. Steel is durable but prone to corrosion. Ceramic offers robustness and resistive properties, but it may be more fragile. Don’t forget about lubrication; the right type can extend bearing life significantly. Sometimes, it's easy to overlook the environmental conditions. High temperatures or humidity levels can affect performance.

Remember that achieving perfection in selection is challenging. Mistakes can happen. Perhaps the chosen size feels right, but it may not be suitable in real-world tests. Testing your selection under actual working conditions can bring clarity. Always be open to adjustments based on performance outcomes. It’s all part of the learning curve.

When selecting the right ball bearing, material choice is crucial. Different applications require specific materials to perform optimally. Common materials include steel, ceramic, and plastic. Each has its unique properties and applications.

Steel bearings are often favored for their durability and strength. They excel in high-load situations but may rust or corrode. Consider the environment. If moisture is present, steel may not be ideal. Stainless steel is a better option in such cases, but it can be more expensive.

Ceramic bearings are lightweight and resistant to corrosion. They have low friction, but their brittleness can be a downside. In contrast, plastic bearings are less durable but highly resistant to chemicals. They work well in environments where metal corrosion occurs. Reflect on the operating conditions and forces at play. Choosing the right material impacts bearing performance and lifespan.

| Tip Number | Tip Description | Material Options | Load Capacity | Speed Rating |

|---|---|---|---|---|

| 1 | Consider the application requirements | Chrome Steel | Moderate | Up to 3000 RPM |

| 2 | Evaluate the operating environment | Stainless Steel | High | Up to 5000 RPM |

| 3 | Assess the required precision | Ceramic | Very High | Up to 6000 RPM |

| 4 | Determine the lubrication type | Polymer | Moderate | Up to 4000 RPM |

| 5 | Review size and fit tolerance | Brass | Low | Up to 2000 RPM |

| 6 | Consider temperature limits | Plastic | Low | Up to 1500 RPM |

| 7 | Examine cost vs performance | Hybrid (steel/ceramic) | High | Up to 8000 RPM |

| 8 | Check for noise levels | High Carbon Steel | Moderate | Up to 3500 RPM |

| 9 | Research manufacturer's reputation | Nickel Alloy | High | Up to 4500 RPM |

| 10 | Get expert recommendations | Titanium | Very High | Up to 7000 RPM |

When choosing the right ball bearing, it’s crucial to evaluate load capacity and performance characteristics. Load capacity directly impacts how much weight a bearing can handle. Consider both static and dynamic loads. Static load refers to the weight a stationary bearing can support. Dynamic load indicates the weight while in motion. Ensure these capacities align with your application needs.

Analyze performance characteristics too. Factors like speed ratings, temperature range, and lubrication methods play significant roles. A high-speed bearing may not sustain heavy loads. Conversely, a bearing designed for high loads may operate poorly at high speeds. Each scenario requires thoughtful consideration.

Reflect on the weight of the application. Underestimating load can lead to rapid wear. Overestimating can cause unnecessary expenses. Gather data on load requirements before you select a bearing. Testing different options may reveal surprises. It might even highlight flaws in initial assumptions. Always keep learning about how these factors interact in real-life applications.

When selecting ball bearings, maintenance is often overlooked. Ensuring longevity demands consistent and proper care. Regular inspections help identify issues early. A simple visual check can reveal rust or wear. If you notice any irregularities, consider immediate action.

Cleaning your ball bearings is crucial. Dust and dirt can accumulate, leading to reduced performance. Use a soft brush to remove debris. You might think lubrication is optional, but it is not. Applying the right lubricant can prevent friction. Too much or too little can both be problematic. Aim for a balanced approach.

Storage matters too. Keep your ball bearings in a cool, dry place. Excessive heat or moisture can lead to damage. If you aren't using them for a while, wrap them in a cloth. Utilize desiccants to absorb moisture. Such details matter in ensuring a longer lifespan. Reflect on these points to avoid mishaps later on.