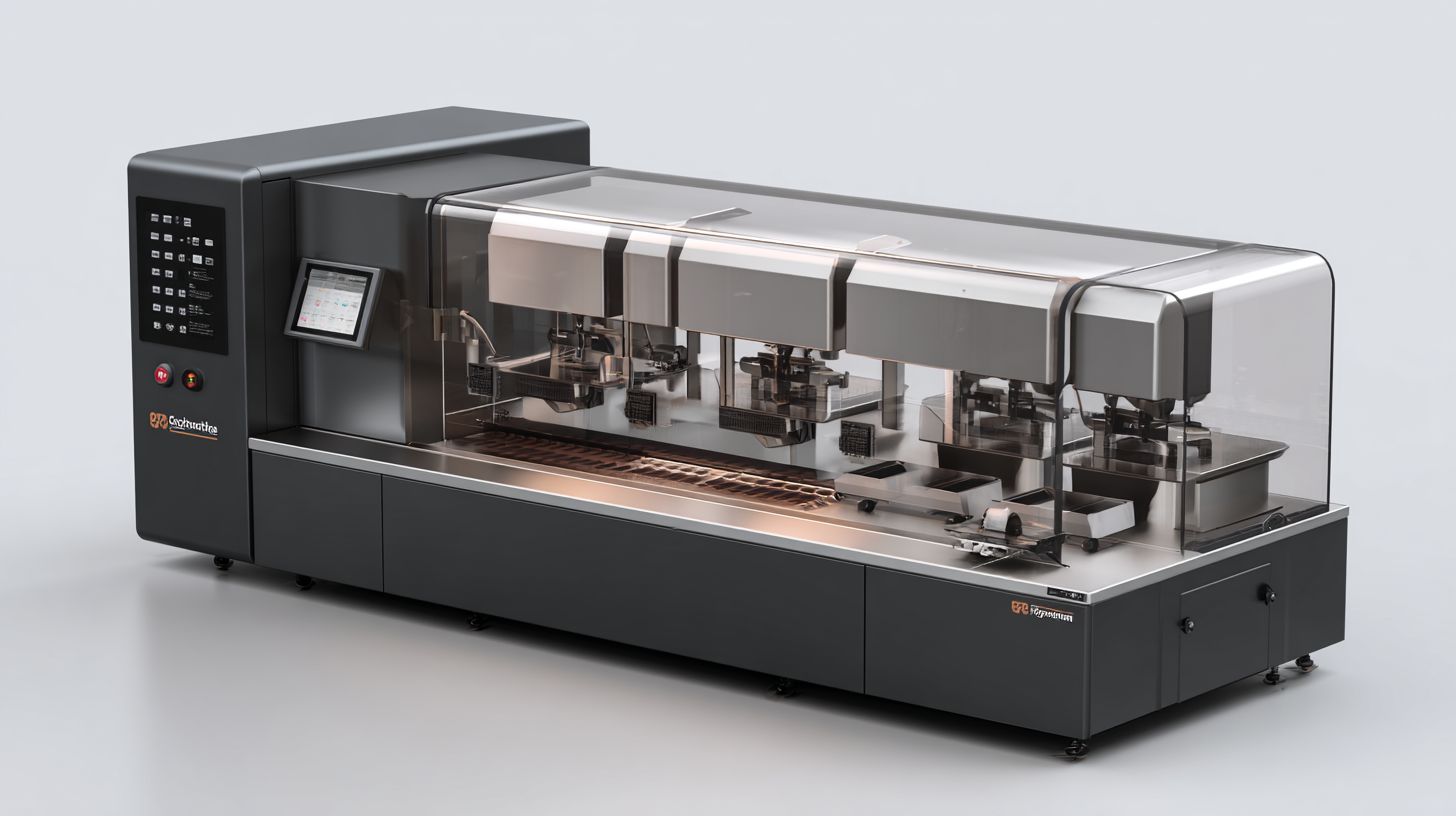

The chocolate industry is experiencing unprecedented growth, with projections estimating that the global chocolate market will reach a value of over $200 billion by 2025. As production demands increase, manufacturers are turning to advanced machinery to enhance their efficiency and product quality. One critical piece of equipment in this process is the Chocolate Enrobing Machine, which enables producers to create a variety of confections with a perfect chocolate coating.

Investing in a high-quality chocolate enrobing machine can significantly enhance your production capabilities while ensuring optimal product quality. These machines provide a uniform coating of chocolate on confections, which not only improves visual appeal but also enhances the flavor profile. By choosing a reliable enrobing machine, manufacturers can increase efficiency, reduce material waste, and maintain consistency across batches.

When selecting an enrobing machine, consider these tips: First, evaluate your production volume and choose a machine that can handle your needs without frequent breakdowns. Second, pay attention to the machine's temperature control features; precise temperature regulation is crucial for achieving the perfect chocolate coating. Finally, opt for a machine that is easy to clean and maintain, which will save time and reduce operational costs in the long run.

Moreover, a high-quality enrobing machine can offer versatility in your product offerings. With adjustable settings, you can experiment with different types of chocolate and coatings, allowing your brand to stand out in a competitive market. This investment not only pays off in production efficiency but also elevates the quality of your confections, ensuring that your customers return for more.

When selecting a chocolate enrobing machine, understanding the key features is crucial to ensure optimal production efficiency. First and foremost, the size and capacity of the machine must align with your production goals. Machines come in various sizes, from small tabletop models for limited batches to large industrial enrobers designed for high-volume output. Consider your workspace and the scale of your operations to choose a machine that fits seamlessly into your production line.

Another significant feature is the temperature control system. Chocolate enrobing requires precise temperature management to maintain the quality of the chocolate coating. Look for machines equipped with advanced temperature regulation systems that keep the chocolate at the optimal melting point. Additionally, consider machines that offer adjustable speed settings and variable coating thickness, allowing for customization based on the products being enrobed. These features not only enhance the quality of the coating but also help streamline the manufacturing process, improving overall efficiency and productivity.

| Feature | Description | Importance | Considerations |

|---|---|---|---|

| Production Capacity | The amount of product that can be enrobed per hour. | High | Match capacity with production demands. |

| Temperature Control | Ability to maintain optimal chocolate temperature. | High | Ensure stability of chocolate quality. |

| Automation Level | Degree of automation in the enrobing process. | Medium | Consider labor costs and skill levels. |

| Ease of Cleaning | How easily the machine can be disassembled and cleaned. | High | Impact on production downtime. |

| Size and Footprint | Dimensions of the machine and space required. | Medium | Space limitations in your facility. |

| Materials Used | Quality of materials used in construction. | High | Durability and longevity of the machine. |

| Versatility | Ability to handle different types of products and coatings. | Medium | Future-proofing for product line changes. |

When it comes to chocolate production, choosing the right enrobing machine is crucial for achieving high-quality results. The market offers a variety of chocolate enrobing machines, each designed to meet specific production needs. One major distinction lies between the batch and continuous enrobing machines. Batch machines are ideal for smaller productions and artisanal operations, providing flexibility and ease of cleaning. In contrast, continuous machines are suited for larger-scale production, allowing for a streamlined process and higher throughput.

Another important factor to consider is the type of enrobing technology used. Some machines utilize air-cooled enrobing, which is effective for certain chocolate types, while others employ a water-cooled system, ideal for maintaining temperature consistency during high-speed production. Additionally, the inclusion of features such as adjustable enrobing speeds, temperature controls, and interchangeable molds can significantly impact efficiency and product quality. Understanding these differences is essential for selecting an enrobing machine that aligns with your production goals and chocolate handling requirements.

In the competitive chocolate manufacturing industry, production efficiency is paramount, and investing in a high-quality chocolate enrobing machine can significantly enhance output. According to a recent report by Smithers Pira, the global chocolate market is projected to grow at a CAGR of 4.5% from 2023 to 2028, highlighting the increasing demand for processed chocolate products. Enrobing machines, which allow for the uniform coating of confections, can boost production rates by up to 50%, ensuring that manufacturers can keep pace with this growing market trend.

Moreover, advanced enrobing machines improve the consistency of chocolate coating, reducing product waste and ensuring a higher-quality finish. A study from the International Cocoa Organization indicates that efficiency improvements in chocolate production could lead to cost savings of approximately 20-30% in the long run. The precision offered by modern enrobing technology not only streamlines the production process but also enhances the aesthetic appeal of the final product, which is crucial in attracting increasingly discerning consumers. By choosing the right enrobing machine, chocolate manufacturers can optimize their production processes and improve profitability while meeting the rising global demand for chocolate products.

When it comes to chocolate production, investing in an automated chocolate enrobing machine can yield significant long-term cost savings. These machines streamline the enrobing process, reducing labor costs and minimizing product waste. By automating tasks that would typically require skilled workers, businesses can operate more efficiently and allocate their human resources to other critical areas. This not only boosts productivity but also enhances consistency in production, leading to a higher quality product that can help increase sales.

Moreover, automated enrobing solutions often come equipped with advanced technology that optimizes chocolate usage. These machines ensure precise coverage and reduce the amount of excess chocolate that can accumulate and go to waste. By utilizing these innovative systems, companies can effectively lower their raw material costs over time. Investing in an automated system not only improves operational efficiency but also positions businesses for growth in a competitive market, enabling them to respond to increasing demand without sacrificing quality or profitability.