The chocolate industry continues to experience robust growth, driven by increasing consumer demand for premium products and innovative chocolate offerings. According to a report by Research and Markets, the global chocolate market is expected to reach $161.56 billion by 2024, growing at a CAGR of 4.6% from 2019. This trend not only highlights the importance of quality and process efficiency in chocolate production but also underscores the critical role of technology, particularly in the enrobing process.

A Chocolate Enrobing Machine is essential for manufacturers looking to enhance their production capabilities and meet the rising expectations of consumers for beautifully coated chocolate products. This machinery allows businesses to achieve uniform coverage, improve product quality, and increase output efficiency. With a variety of machines available on the market, selecting the right Chocolate Enrobing Machine tailored to specific business needs can significantly impact operational success and profitability.

As more manufacturers seek to optimize their production processes, understanding the core features, capabilities, and technological advancements of different enrobing machines becomes paramount. This guide aims to provide insights into the critical factors to consider when choosing the best Chocolate Enrobing Machine, ensuring that businesses can make informed decisions that align with their goals and production requirements.

Chocolate enrobing machines are essential for businesses looking to elevate their chocolate-making process. These machines coat confections, snacks, or baked goods with a smooth layer of chocolate, ensuring a professional finish while enhancing flavor. Understanding the functions of these machines can help in selecting the right one for your specific needs, whether you're a small artisan chocolatier or a large-scale manufacturer.

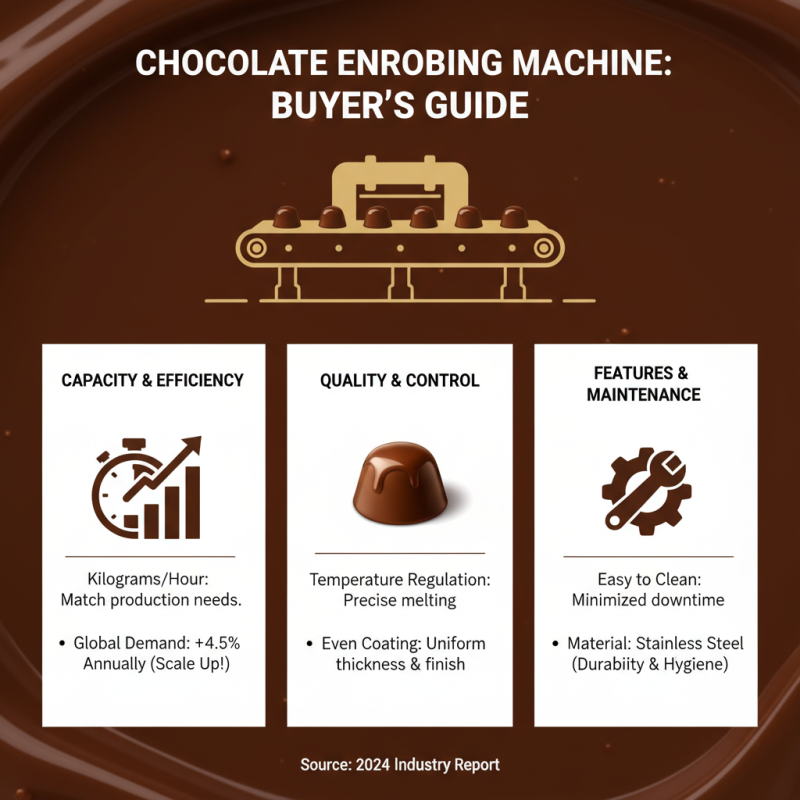

One key feature to consider is the type of enrobing technology used in the machine. Some machines utilize a cascading method where chocolate flows over the product, while others may use a curtain system for more precise coating. It’s important to evaluate the volume and size of your products to ensure compatibility. Additionally, look for features such as temperature control, which is crucial for maintaining the quality of the chocolate and achieving a glossy finish.

Tips: When choosing a chocolate enrobing machine, assess your production needs first. If you plan to produce multiple types of confections, consider a machine that offers customization options. Also, pay attention to the cleaning and maintenance aspects of the machine; easy disassembly can save time and improve hygiene. Finally, exploring user reviews and testimonials can provide valuable insights into the machine's performance in real-world settings.

When selecting the best chocolate enrobing machine for your business, it's crucial to consider several key factors that can significantly impact your production efficiency and product quality. One of the primary factors is the machine's capacity, which is often measured in kilograms per hour. According to a recent industry report, the global demand for chocolate is expected to grow by approximately 4.5% annually, forcing manufacturers to scale up their operations. Thus, choosing an enrobing machine that can meet your production needs while maintaining high speed and efficiency is essential.

Another important consideration is the machine's temperature control and automation capabilities. Precise temperature regulation is vital for achieving a consistent chocolate coating, as fluctuations can lead to undesired textures and appearances in the final product. Industry analyses indicate that companies utilizing advanced enrobing technologies with automated features can reduce labor costs by up to 20%, while also minimizing errors associated with manual processes. Additionally, the ability to integrate with existing production lines can streamline operations and enhance overall productivity, making it a vital factor during selection.

When selecting the best chocolate enrobing machine for your business, it is essential to understand the various types available and how they align with your production needs. The two primary categories of enrobing machines are batch and continuous flow systems. Batch machines are ideal for smaller operations or specialty confections, allowing for flexibility in production volumes. According to industry reports, demand for smaller batch enrobing units has surged by 25% annually, driven by the growing artisanal chocolate market. These machines enable manufacturers to create unique flavor combinations without a substantial investment in larger systems.

In contrast, continuous flow enrobing machines cater to high-volume manufacturers, offering efficiency and consistency for mass production. The global chocolate market is projected to exceed $210 billion by 2025, encouraging companies to adopt these automatic systems to boost output. Continuous enrobing machines typically feature advanced technology that can maintain precise temperature controls and coating thickness, which are crucial for ensuring product quality. A recent study indicated that automated enrobing processes can increase production efficiency by up to 40%, making them an attractive option for businesses looking to scale operations while maintaining quality standards.

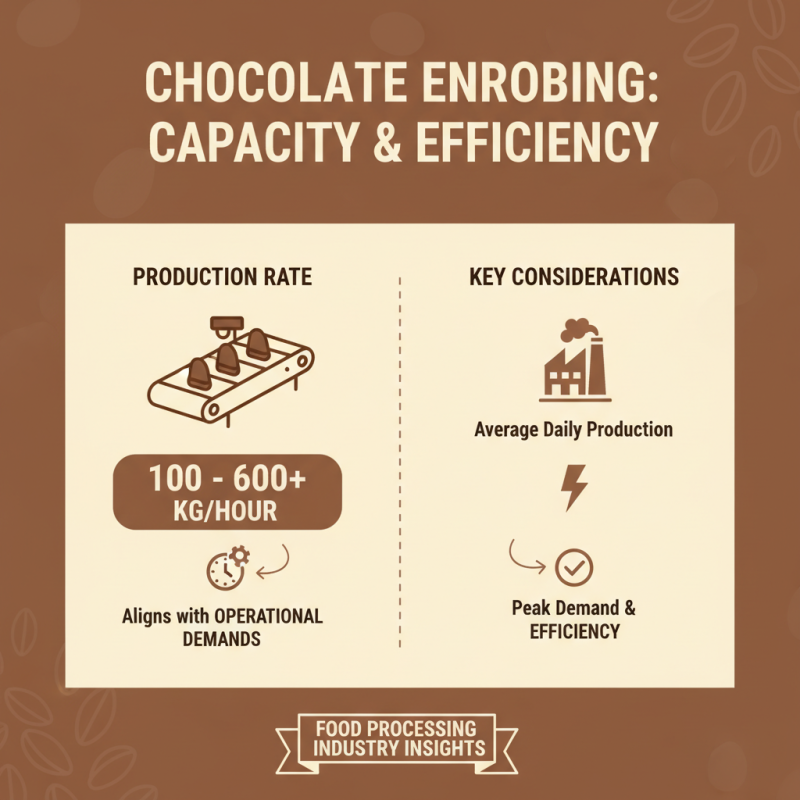

When evaluating production capacity and efficiency needs for chocolate enrobing machines, it is crucial to align equipment specifications with the business's operational demands. The production rate is a primary factor; machines can vary significantly, offering throughput from 100 kg to over 600 kg of enrobed product per hour. A report by the Food Processing Industry Association indicates that chocolate manufacturers must consider their average daily production to ensure the machine can accommodate peak demand without compromising efficiency.

Moreover, energy consumption and resource utilization play vital roles in efficiency. According to recent studies, modern enrobing machines exhibit a reduction in energy usage by up to 30% compared to older models, due to advancements in technology and materials. This not only lowers operational costs but also supports sustainability goals. Businesses should analyze their energy requirements and select machinery that balances production output with energy efficiency. Selecting the right chocolate enrobing machine means looking beyond just the price; understanding the relationship between production capacity and machine efficiency is crucial for long-term profitability and sustainability in the chocolate industry.

When evaluating the budget and cost-effectiveness of a chocolate enrobing machine, it is essential to consider not only the upfront purchase price but also the long-term operational costs. According to a recent industry report from the International Cocoa Organization, the global chocolate market is projected to grow significantly, with a compound annual growth rate of 4.4% through 2025. This growth means that investing in the right machinery can enhance production efficiency and quality, directly affecting profit margins.

Operational efficiency plays a crucial role in determining cost-effectiveness. Advanced enrobing machines can automate processes that would traditionally require manual labor, thus reducing labor costs. The Machinery Manufacturers Association reports that companies employing automation can save up to 30% on labor expenses while increasing output by 20%. Additionally, factors such as energy consumption and maintenance costs should not be overlooked. Machines that utilize energy-efficient technology and require minimal maintenance can lead to significant savings over time, making them a savvy investment for businesses looking to expand their operations without inflating their budgets.

Ultimately, making an informed decision involves a careful analysis of the total cost of ownership, including purchase price, operational expenses, and potential savings through enhanced efficiency. By conducting a thorough cost-benefit analysis, businesses can choose the best chocolate enrobing system that aligns with their financial capabilities while setting the stage for future growth in a competitive market.

| Machine Type | Production Capacity (kg/hour) | Price Range (USD) | Energy Efficiency Rating | Maintenance Frequency | Warranty Period |

|---|---|---|---|---|---|

| Continuous Enrober | 100 | $25,000 - $40,000 | A+ | Monthly | 2 years |

| Batch Enrober | 50 | $15,000 - $25,000 | B | Every 3 months | 1 year |

| Small Scale Enrober | 20 | $10,000 - $15,000 | B+ | Every 6 months | 1 year |

| Custom Enrober | Variable | $40,000 - $100,000 | A++ | As needed | 3 years |